Waste sector emissions ticked up in 2023, unreleased EPA report finds

Emissions from the waste sector ticked up in 2023, snapping a three-year streak of declines, according to a chapter of the U.S. Greenhouse Gas Emissions and Sinks report released by the U.S. EPA.

Waste emissions totaled 165.8 million metric tons of carbon dioxide equivalent in 2023, compared to 165.1 million metric tons of CO2e the prior year, per the report.

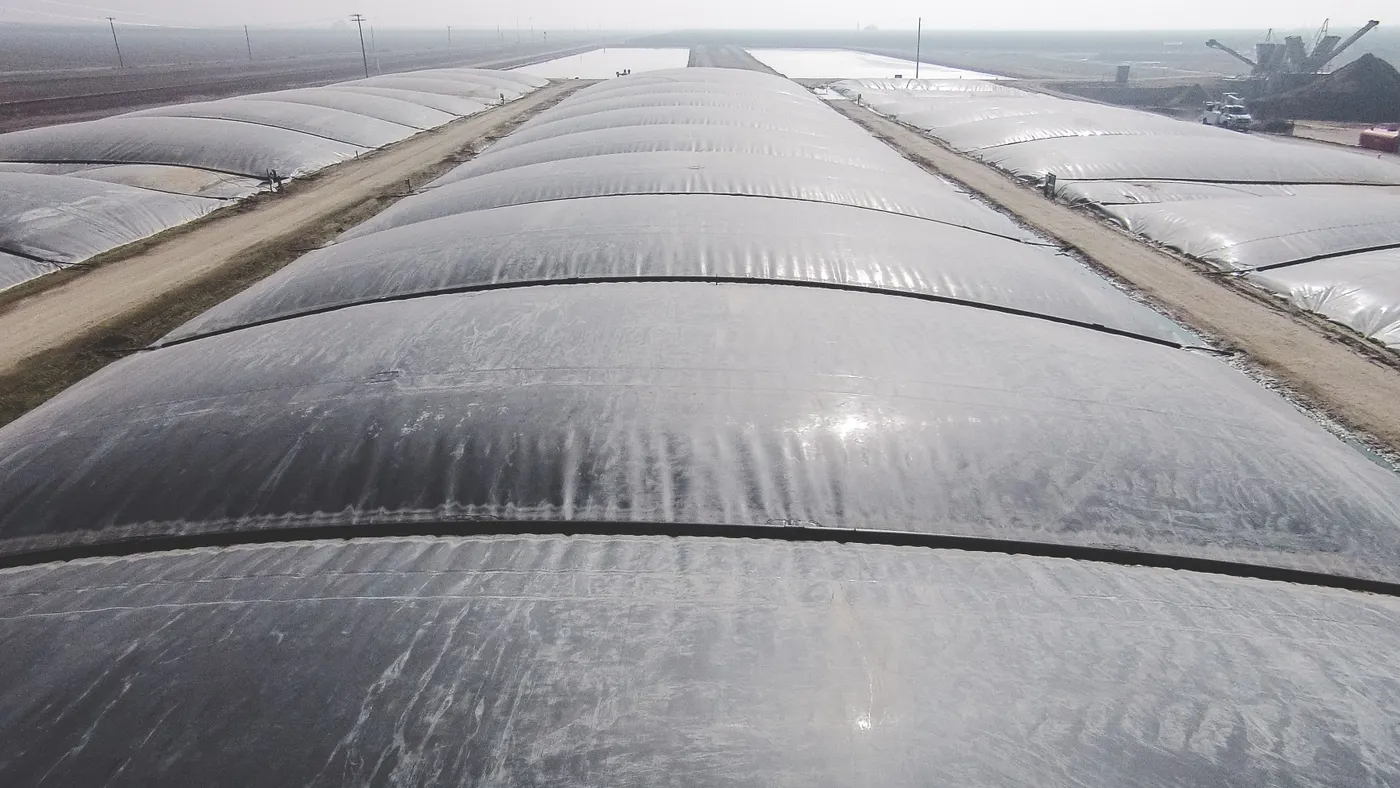

Landfills continue to represent roughly three-quarters of the waste sector's emissions. They contributed 119.5 million metric tons of CO2e in 2023, up slightly year over year but below 2021 levels. Wastewater treatment is the second largest contributor to the waste sector's emissions with 21.1 million metric tons of CO2e. Composting is the third largest contributor with 2.6 million metric tons of CO2e.

Overall gross emissions in the U.S. declined 2.3% from 2022 to 2023, according to an executive summary of the report. The country's overall methane emissions have declined 21.4% since 1990, the report's baseline year.

The EPA was set to release a full version of the 2023 report in 2025, but it was reportedly paused following the change in administration. A draft version of the waste chapter was one of two, along with agriculture, to be released by the agency.

The Environmental Defense Fund obtained a copy of the full, completed report via a Freedom of Information Act request after the EPA declined to publish it or submit it to the United Nations, something it's done since the late 1990s. The agency has not commented publicly on its decision to forego publishing the report.

The Trump administration has targeted emissions reporting efforts in recent months, including through proposed changes to the EPA’s Greenhouse Gas Reporting Program. Environmental groups argue such changes would reduce transparency and data availability at a time when global agreements demand a reduction in greenhouse gas emissions. The agency has said it would consider longstanding waste industry concerns about the accuracy of landfill emissions estimates in its program changes.

Landfills are the third largest source of methane emissions in the country, behind enteric fermentation in cattle and natural gas systems. Overall methane emissions fell 2% year-over-year in 2023, in part due to a decrease in beef cattle populations and decreased emissions from natural gas distribution, transmission and storage. While landfill emissions increased over the short term, improved landfill gas collection systems and landfill closures reduced the facilities’ emissions by 39.6% between 1990 and 2023.

The EPA continually updates its emissions estimates for each sector, including waste. That means data from last year's report has since been updated and looks different in the latest report. The agency noted that changes to MSW and industrial waste landfill activity data, as well as wastewater and anaerobic digestion estimates, resulted in lower emissions estimates for the industry across multiple years.

The annual report also tracks greenhouse gas emissions from incineration of waste in its energy chapter. MSW combustion created 12.4 million metric tons of CO2e in 2023. That's down 3.7% from waste incineration emissions in 1990, and is roughly the same as 2021 and 2022 levels.