A recent report by Waste Management shows untapped capacity throughout the materials recovery chain, at a time when demand for faster recycling progress is increasing on multiple fronts in the United States.

This release follows a shareholder resolution from Trillium Asset Management and As You Sow earlier this year that sought new data on the plastics recycling systems and relevant policies of the nation's largest residential recycler. The resulting 20-page report – which draws on research by consultants Resource Recycling Systems, More Recycling and Skumatz Economic Research Associates – offers a range of information that some hope will deliver more context to brands and policymakers as they plan next steps. A forthcoming report from Republic Services, also based on a resolution by As You Sow, is expected to complement this work.

While many are still processing this report's contents, and soliciting feedback, multiple initial takeaways have emerged.

1. Significant work remains to hit circular economy targets for plastics

Noting that it no longer exports any plastics – except for "high-grade, source-separated commercial film to reputable high-quality end markets" – Waste Management points to a number of domestic end markets for residential material. When it comes to plastics that have viable markets, the company highlights only polyethylene terephthalate (PET), high-density polyethylene (HDPE) and polypropylene (PP).

The Southeast is Waste Management's highest volume destination for end buyers of these plastics, though the Great Lakes is another prime location. But when it comes to regions accepting the most material generated outside their borders, the Southeast is handling the largest imported volumes by far across all categories.

The report goes into greater detail on the regional factors around PET, HDPE and PP, but one of the clear findings is much more can be done within the current system to achieve brands' stated circular economy targets. In many cases, it's more common for these recycled resins to be downcycled in products different than their original use. For example, according to the report, only 21% of PET collected for recycling is turned back into food grade bottles and most of that activity comes from the 10 bottle bill states.

For brands that have circular economy targets, this is seen as a sign that beyond trying to incentivize the collection of more material they can start by buying more material already in the system.

“This is not only the right thing to do, it’s really what these companies need to do to reduce the risks of their brands," said Conrad MacKerron, senior vice president of As You Sow. “Every bottle that they buy up ... they’re keeping out of mismanagement."

In MacKerron's view, major brands should be prioritizing the use of recycled content even if the price is "higher or substantially higher" than virgin.

Beyond the ongoing need to do this for PET and HDPE containers, there appears to be growing sentiment that PP offers untapped potential as well. While Waste Management's volume of PP sold to end markets increased by 10% in 2019, and it said market demand is growing, not everyone is convinced the already low values can compete with virgin pricing as more production capacity comes online.

“The report shows the dire situation for recycling post-consumer PP#5 due to lack of processing capacity in most of the country," said Jan Dell, an independent engineer with The Last Beach Cleanup, via email. "Unless the plastic, product and retail companies who profit from the sales of PP#5 products directly invest in significant processing capacity in all regions and guarantee recyclers a sufficient, long term price for collecting and sorting PP#5, it will not happen as public and consumer funding is nonexistent due to the economic crisis.“

2. Residential MRF capacity is not being maximized amid calls for more recycling

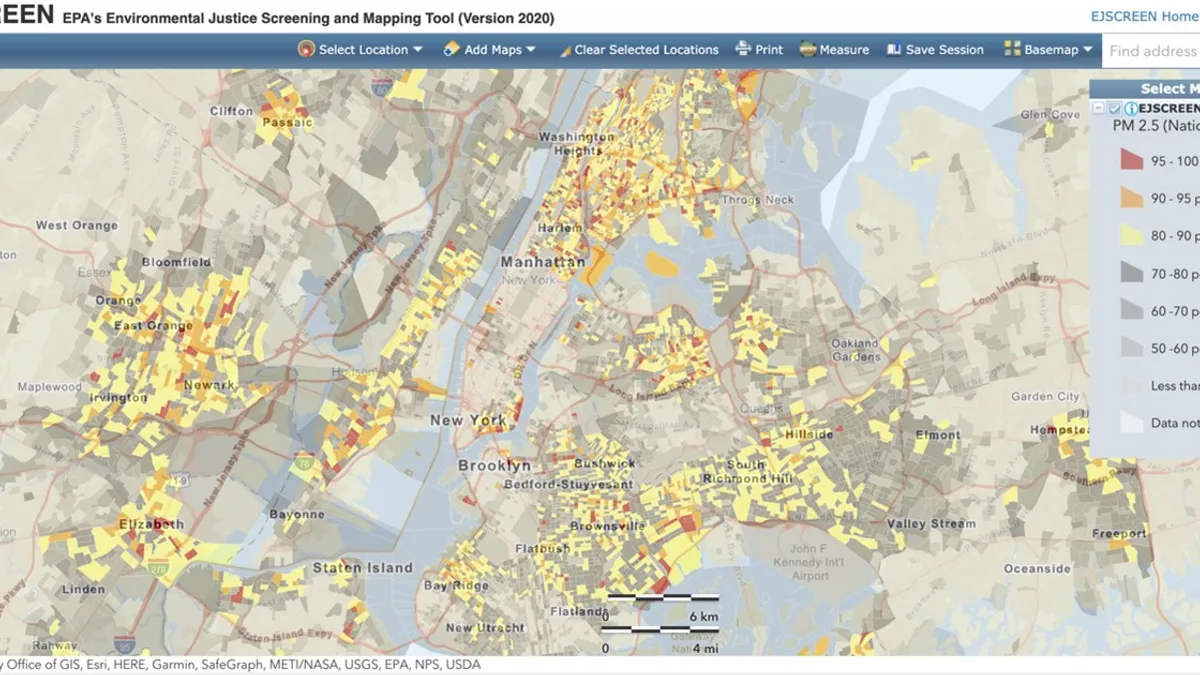

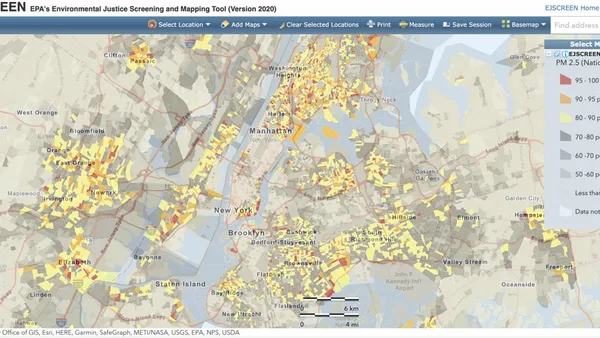

According to Waste Management, more than 28% of MRF processing capacity (the equivalent of 6.6 million tons of material) in the U.S. is not being utilized. The New York-New Jersey and Mid-Atlantic areas have the highest shares of open capacity. Sizable open capacity also exists in the Pacific Southwest and the Southeast, followed by smaller amounts in every other area – except New England and the Midwest, which are largely full.

Amid years of discussion about needing to expand recycling infrastructure, this data appears to show more work can also be done to maximize use of existing elements.

“What jumped out at me was the excess MRF capacity," said Will Sagar, executive director of the Southeast Recycling Development Council. "We’ve got a lot of unmet demand for material and according to this we’ve got the processing capacity and we’ve got recycling collection over quite a bit of the population."

Sagar's group works with public and private sector players throughout the recycling supply chain, including manufacturers that say they can't always get enough recycled content. While work has been ongoing for years to boost collection activity, it appears there is more to be done.

"It seems we need to improve the participation rate," said Sagar. “If we’ve got the MRF capacity, collection capacity is pretty straightforward."

3. Recent collection and education tactics have shown results

The recycling sector has been increasingly focused on converting to cart-based collection, with a heavy emphasis on quality control following changing market dynamics. And while the related switch to single-stream that often entails remains a source of debate due to quality concerns, this report shows Waste Management is committed to that approach.

According to the company, it purchased 500,000 new carts across 2018 and 2019. This led to a 100,000 ton increase in residential material collected and the company now supports automatic cart delivery in areas with curbside recycling programs.

When paired with targeted education, Waste Management said this has led to more material and cleaner material heading to MRFs. It reports inbound contamination rates have declined from an average of 25% in recent years to "just over" 17%. The company also notes a goal, which has not been widely publicized before, of knocking inbound contamination rates down to 10% by 2025.

4. MRF investments are continuing with room for more

Waste Management's report describes the key to improved recycling as a combination of better collection access and ongoing education with the strategy that "collection investments must match facility investment."

Along these lines, recent investments include four new or upgraded MRFs and 100 equipment upgrades at other MRFs. Per the report, upgrades such as screens and optical sorters have reduced residual rates and helped yield higher prices for better quality end products. While the company notes upgrades at one facility reduced its residual rate to 6.3%, lower than industry averages, a company-wide average residual rate is not reported.

Among its 49 residential MRFs, the company reports 48% of them fall into two categories where recent investments have been made. An additional 25% of the company's facilities are slated for upgrades within the next three years, while the remaining 26% "have no near term plans for upgrades." The company notes the 13 sites in this latter category are smaller, and only account for 9% of its overall processing capacity.

Underlying this assessment is Waste Management's continued stance that processing investments are only worthwhile for materials "with enough volume to create full loads on a regular basis and with viable end markets." Materials fitting the company's criteria include "cardboard, aluminum and tin/steel cans, PET, HDPE and PP bottles, and glass (where end markets exist)." The latter characterization glass taps into a broader debate in the industry about how to best capture the material, as manufacturers say they want more of it, but fits with the company's prior comments.

5. Waste Management's policy positions are shifting slightly

Waste Management's opposition to a major packaging policy bill in California during the 2019 legislative session (a position it maintained this year) was one inspiration behind the shareholder resolution. The company's stance on broader extended producer responsibility (EPR) policies had generally been viewed as oppositional, but it began showing more nuance earlier this year and clarified that position in April.

Now, the company says it supports EPR for certain "hard-to-handle" categories such as electronics, batteries, lighting, paint and other materials "for which there are no funding or handling systems readily available to consumers." Otherwise, it is skeptical of EPR for packaging in part because it hasn't seen them drive sufficient changes in market demand or product design. The company does support "advanced disposal fees" and related structures that factor recycling costs into product pricing, which could leave the door open for stewardship models that don't change the company's control of processing infrastructure.

While the report's earlier sections note benefits of bottle bill programs in terms of generating cleaner material more apt to be recycled back into new beverage containers, the company's stance on container deposit laws was left open.

“The quality and quantity data about beverage containers make a clear case for deposit laws," said Susan Collins, president of the Container Recycling Institute. "They very much emphasize that only deposit material is being used to make new bottles again ... That was the most forthright I’ve ever seen Waste Management be about the fact that the quality is so different."

Historically, large industry service providers or their trade associations have resisted the establishment of new bottle bills or the expansion of existing ones. Waste Management's policy section does not include a specific stance on bottle bills and the company confirmed it views these policies separately from EPR.

"We consider EPR to be a funding mechanism to support recycling programs, where bottle bills create financial incentives for consumers to return their bottles for recycling," said spokesperson Janette Micelli via email. "While we noted in the paper that PET from bottle bills plays an important role in food grade recycling, not all PET bottles from bottle bills are recycled into new bottles, and far more PET is collected in curbside programs. The convenience of curbside recycling plays a critical role in recycling in the U.S. Bottle bills warrant a separate discussion outside of EPR."

Beyond establishing support for pay-as-you-throw programs and recycling mandates, Waste Management also mentions its support for recycled content legislation. The company notes supporting a Washington bill vetoed earlier this year and one under consideration in New Jersey. While it was not registered as a supporter of a bill recently passed in California, the company said at the time it was "pleased" with that outcome.