Dive Brief:

- Ovivo, a company that provides PFAS remediation technologies for water and wastewater, has signed a deal to provide a new commercial ozone foam fractionation process from Australian PFAS mitigation company Evocra.

- The exclusive licensing agreement allows Ovivo to now provide the PFAS treatment technology in addition to its PFAS destruction technology offerings. The combined services for wastewater and leachate will be available in the U.S. and Canada, the companies said.

- Ovivo has been piloting a combined ozone foam fractionation and electrochemical oxidation process at a site in Alabama, as well as conducting separate studies on landfill leachate. Ovivo says the combined process achieves over 99.9% PFAS destruction for leachate.

Dive Insight:

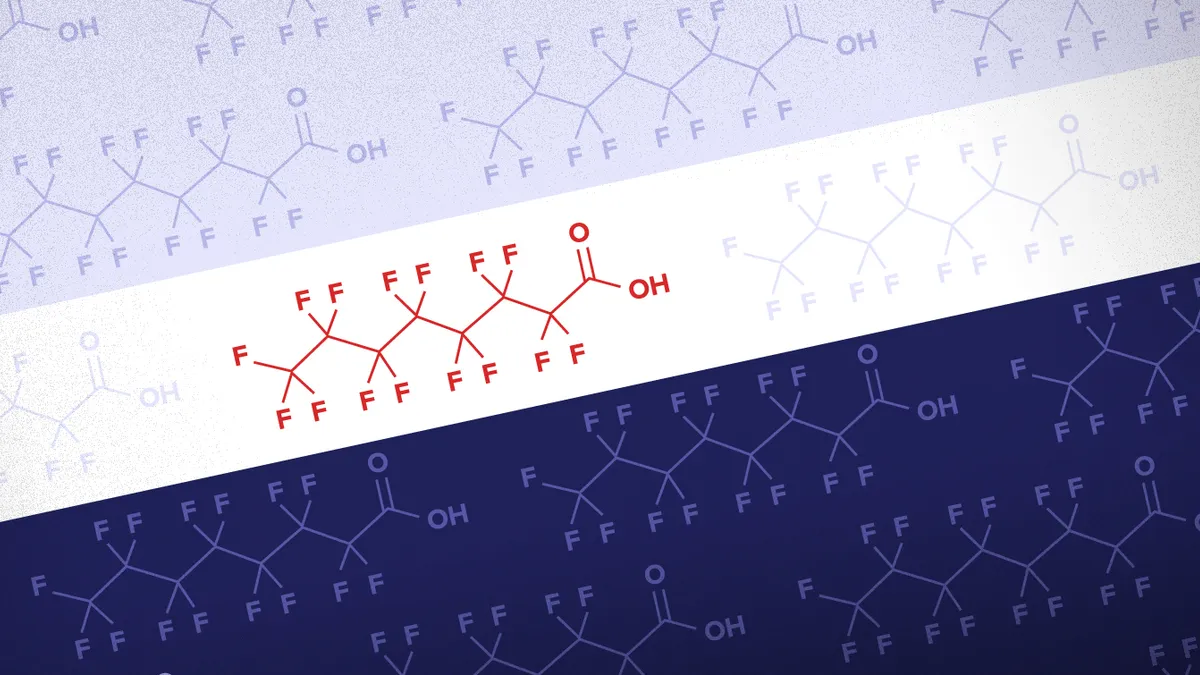

The deal is the latest among PFAS treatment, disposal and destruction businesses aiming to offer a wider and more cost-effective suite of services in the wake of new federal regulations. The U.S. EPA recently set drinking water standards for certain per- and polyfluoroalkyl substances, designated PFOS and PFOA as hazardous substances, and updated destruction and disposal guidance.

Landfill operators and industry analysts say they expect to spend more on PFAS management in coming years, but some hope the competition between PFAS mitigation companies, coupled with rapidly improving technologies, could bring some of those costs down as time goes on. Landfill operators also expect the new regulations will likely lead to more cleanup projects around the country, which could mean landfills start accepting higher volumes of PFAS-containing material.

Evocra’s ozone foam fractionation process separates and concentrates PFAS from wastewater or leachate. Foam fractionation is a common process for PFAS removal, and it’s been a popular option for several waste companies: Casella is conducting a foam fractionation trial at its facility in Vermont, while Waste Connections last year hired Altra Sanexen to provide the technology at two Minnesota landfills. Arcadis, a sustainable design consultant firm, has said foam fractionation is well suited for leachate because of its high solids content.

Tom Leland, Ovivo’s managing director of industrial and PFAS solutions for North America, said Evocra’s version is notable because its process uses both air and ozone, making it a more effective technology. “We believe that the remedy to the PFAS crisis should be focused on easy-to-implement, on-site technologies that don’t just pass the problem along but eliminate PFAS for future generations,” he said in a news release.

Ovivo plans to use the foam fractionation process in combination with a process called electrochemical oxidation, a PFAS destruction technology from E2metrix, a company Ovivo acquired in February. The EPA has listed electrochemical oxidation among four “emerging technologies” in its latest destruction and disposal guidance. The EPA noted the processes “show promise” but said more research is needed on the technologies to understand their effectiveness.

Ovivo says the combination of the two technologies will help expand its offerings “on the large scale needed to address the extensive PFAS contamination found in our environment.” It is still in the process of making the technologies more efficient and gathering information from its pilot project in Alabama.

Ovivo said the pilot in Alabama has shown the foam fractionation process can remove over 90% of “regulated PFAS compounds” — which includes PFOA and PFOS — in a reverse osmosis concentrate. The electrochemical oxidization process then destroys about 85% of PFAS found in the resulting foam, it said. A separate study the company undertook for landfill leachate indicates up to 99.9% destruction of “total detectable PFAS,” the company said. Evocra says its foam fractionation process is also meant to remove PFAS from industrial sewage, fire training ground runoff, and saline surface waters.

Arcadis previously held Evocra’s license for the technology in North America, Ovivo said.